The global shift toward electrification is pushing manufacturers to enhance the performance and scalability of the lithium ion battery module. High-quality, automated solutions are now critical in keeping up with production goals and cost efficiency. This is where LEAD Intelligent plays a key role, offering comprehensive, high-tech solutions that address every step of battery module manufacturing.

LEAD Intelligent Provides Complete Manufacturing Solutions

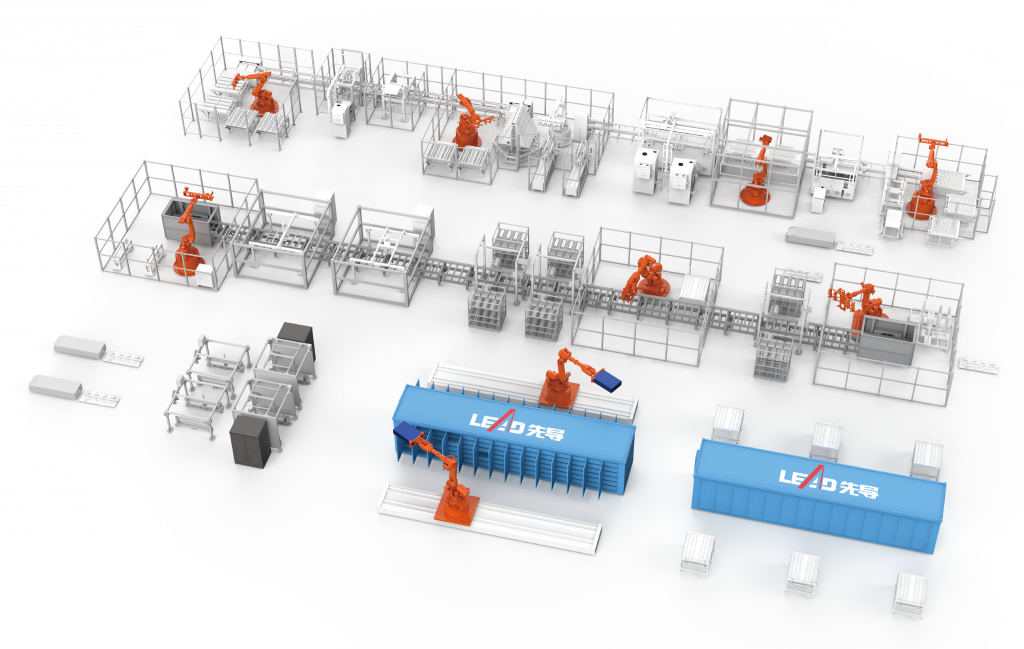

Known for its innovation in battery equipment, LEAD intelligent supports manufacturers with factory planning, core machine development, and entire line system integration. Whether the production involves cylindrical, prismatic, or pouch cell modules—or full PACK assembly—LEAD ensures precision and consistency across all formats of lithium ion battery module production.

Automation Reaching 95%: Enhancing Efficiency and Accuracy

With automation rates reaching up to 95%, LEAD’s systems cover everything from EOL testing to charge-discharge equipment, MES software customization, and intelligent logistics. This drastically improves production speed while maintaining consistent quality throughout each stage of the lithium ion battery module process.

Supporting the Full Lifecycle from Assembly to Disassembly

LEAD Intelligent also offers solutions for module and PACK disassembly, supporting circular manufacturing goals. Their integrated approach includes smart warehousing and automated logistics to reduce downtime and increase throughput.

Customized Solutions for Evolving Manufacturing Needs

As requirements for battery modules grow more complex, LEAD adapts its equipment and systems to fit specific client needs. Their ability to support both high-volume production and specialized projects makes them a vital partner in this sector.

Conclusion

LEAD Intelligent delivers tailored, high-efficiency solutions for lithium ion battery module manufacturing—helping companies meet production demands with precision, automation, and intelligent design.